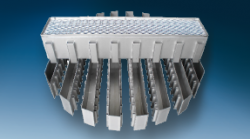

For realizing large and very large operating ranges, Raschig offers a variety of valve tray designs, ranging from round standard valves and caged valves to double disc units. Valve units cover the orifices and direct the vapor stream more horizontally than vertically into the liquid. By this change in direction of the vapor phase, entrainment is reduced significantly in comparison to sieve trays. Special designs for lower pressure drop or high efficiency are available.

Valve trays have large capacities and can realize good separation efficiencies over wide operating ranges.

Valve Types

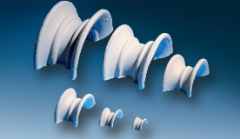

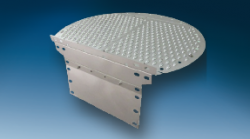

R-V1

Round, movable standard valve with integral legs. Three dimples define the initial lift. Universal purpose, large operation range, variable weights.

R-V1X: Flush seating version.

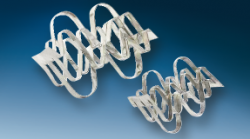

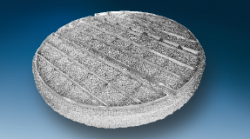

R-T3

Caged, round, movable valve with high mechanical strength. Three lugs in valve plate for initial lift and anti-spin. Low wear, used in fouling services. R-T: Four dimples (instead of lugs) in valve plate.

R-T3-11: Version with small diameter orifice.

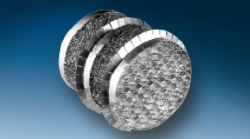

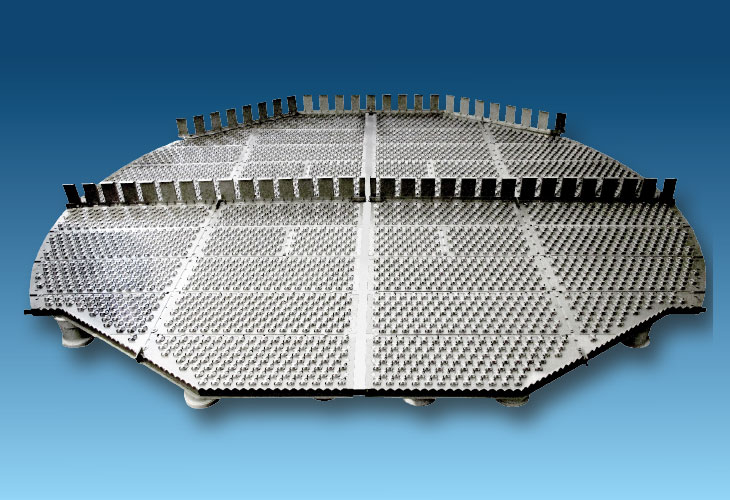

R-T1

Double-disk (orifice cover and ballast plate) within a mechanically strong valve cage. Wide operating range with excellent weeping characteristics.

RA1: Classic three-leg cage.