Research and Development

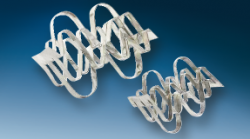

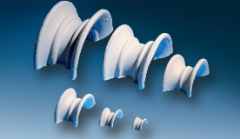

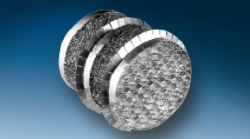

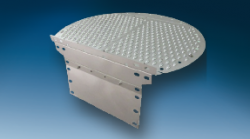

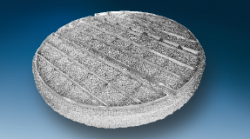

To fulfil our customers’ demand for best separation efficiency, highest through put capacities and lowest pressure drop for our products, RASCHIG continuously develops the most modern random and structured packings as well as mass transfer trays and column internals.

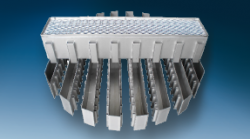

RASCHIG has a team of experts for product development and customized design. Examples include the Raschig Super-Ring and Raschig Super-Pak as well as high performance liquid distribution systems for applications operating under extreme conditions.

In addition to our own test facilities, RASCHIG supports independent test institutes such as Separation Research Program (SRP) or Fractionation Research Incorporation (FRI). These institutes are recognized for their independent process equipment evaluation.

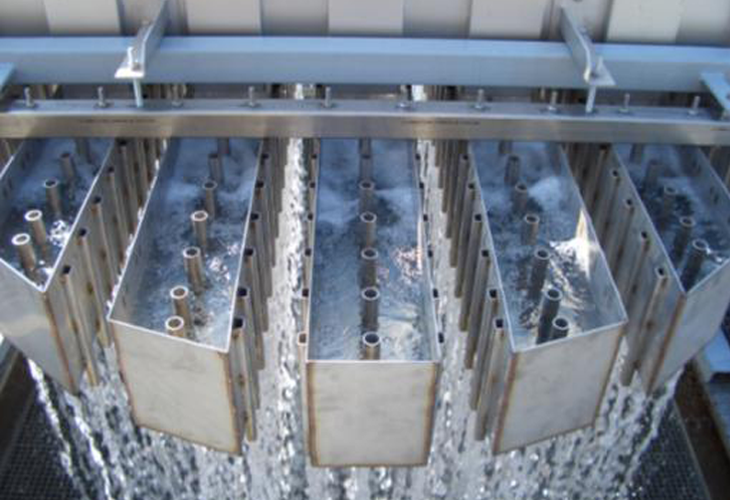

RASCHIG operates one of the world’s largest liquid distributor test facilities.

Ludwigshafen/Germany

Liquid distributor test facility up to 2 m diameter

Rötha/Germany

Liquid distributor test facility up to 12 m diameter

Applications

RASCHIG offers a complete product portfolio relevant for all types of mass transfer towers. Our products are used in distillation, rectification, stripping and absorption towers and can be applied to particle or droplet separation systems. Our products are also used in direct heat exchanger columns as well as in liquid-liquid extraction towers.

Typical applications and services include:

Crude Oil Refinery

Crude Oil Distillation (atmospheric)

Vacuum Distillation

Liquefied Gas Production

Sour Water Stripper

Petrochemical Plants

Ethylene Splitter

Propylene Splitter

Butadiene Production

Benzene Separation

Toluene Separation

Xylene Separation

Environmental Plants

Flue Gas Scrubbing

Waste Water Treatment

Drinking water Treatment

Power Plants

Sulphur Dioxide Separation

Carbon Dioxide Separation

(CCS-Technology)

Natural Gas/Chemical

Plants

De-Ethanizer

De-Propanizer

De-Butanizer

Acid Gas Removal

Air Separation

Titanium Dioxide Production

Chlorine Production

Ammonia Production

Fertilizer Production

Ethyleneoxide Production

Styrene/Ethylbenzene

Separation

Ethanol Separation

Methanol Separation

LNG Recondenser

Ethanolanlagen

Titandioxidanlagen

Methanolanlagen

Chlorgasanlagen

Luftzerlegungsanlagen

Düngemittelanlagen

Refinery Plants

Ethanol Separation